What Is a Paddle Wheel Aerator?

A paddle wheel aerator is an effective tool for raising the oxygen level of a pond. Typically, these units are driven by a tractor with a PTO (power take off) on the rear end. They can be anchored or placed in different positions along a bank. Tractors with PTO power ratings of 45 to 60 horsepower can usually be used as the power source. In some cases, a larger tractor may be needed to move the aerator on a levee. The PTO is also useful in emergency situations, since the paddlewheel can be transported to the site where it will be put to use.

Unlike conventional aerators, which aerate the bottom water layers only, a floating paddlewheel aerator aerates the entire pond. Usually, the unit is equipped with an electric motor and a worm gearbox. This combination helps in reducing the rpm of the aerator. It also facilitates efficient oxygen transfer to the bottom water layers.

A paddlewheel aerator is comprised of a frame of two elongated tube-shaped floats. These floats are attached to the frame at right angles. Another elongated float is fixed on both ends of the first float. Both floats are welded together. Paddles are also welded to the floats. Each paddle is 4 to 6 inches wide and about one inch deep.

A standard paddlewheel aerator can transfer approximately 1.5 to 2.5 pounds of oxygen per hour. This value increases with the size of the paddle wheel and with the rotation speed of the drive unit. Larger-diameter aerators are more effective than smaller-diameter aerators. However, there are some disadvantages with conventional designs, which include the short service life of some components, such as the shaft supports.

The shaft supports and the transmission in the transmission housing have short service lives. Generally, most fuel is used for turning the power train. Hence, it is important to have an effective gear reduction for the aerator. Worm gearing helps in substantially lowering the rpm of the machine.

Alternatively, a paddlewheel aerator can be made using a frame containing three elongated floats connected in a T or H configuration. These floats are secured to the frame in a similar manner. The aerator can be further improved by increasing the depth of the paddles. Increased depths produce stronger currents and better oxygen transfer. For example, during acute dissolved oxygen depletion, the depth of the paddles should be increased to 5 to 6 inches.

To secure the support plate, a further nut is screwed onto the threaded bolt. Alternatively, a non-circular connecting part is used to secure the nut to the support plate. As seen in the FIG. 9, the drive unit is rotated above the water level, and this rotating assembly is connected to the aerator by means of the threaded bolt.

A floating paddlewheel aerator can be fitted with a number of accessories such as feeders for putting out forage. Besides, the aerator can be anchored in a stationary position.

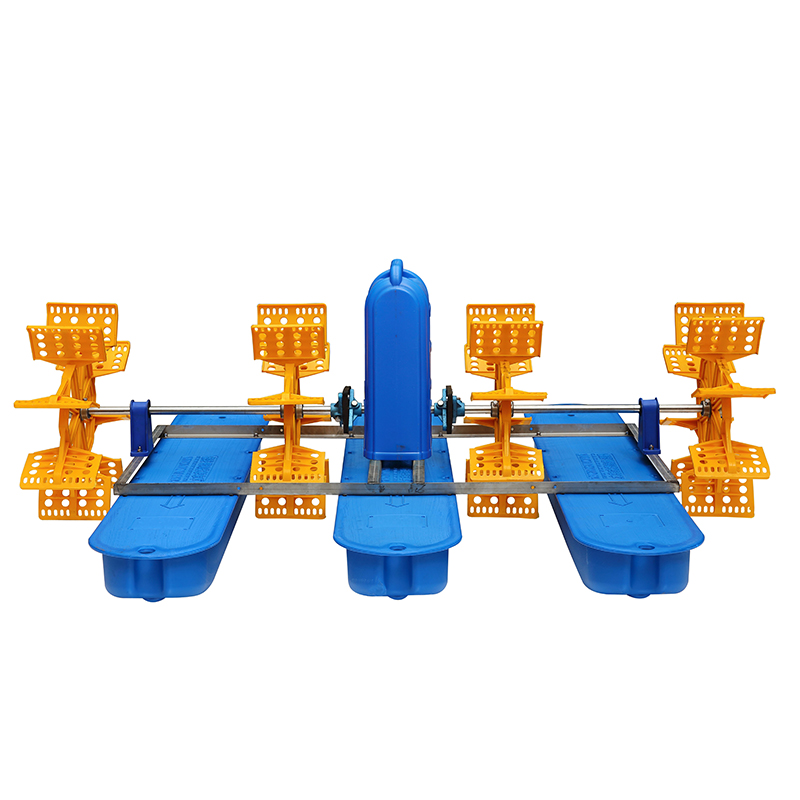

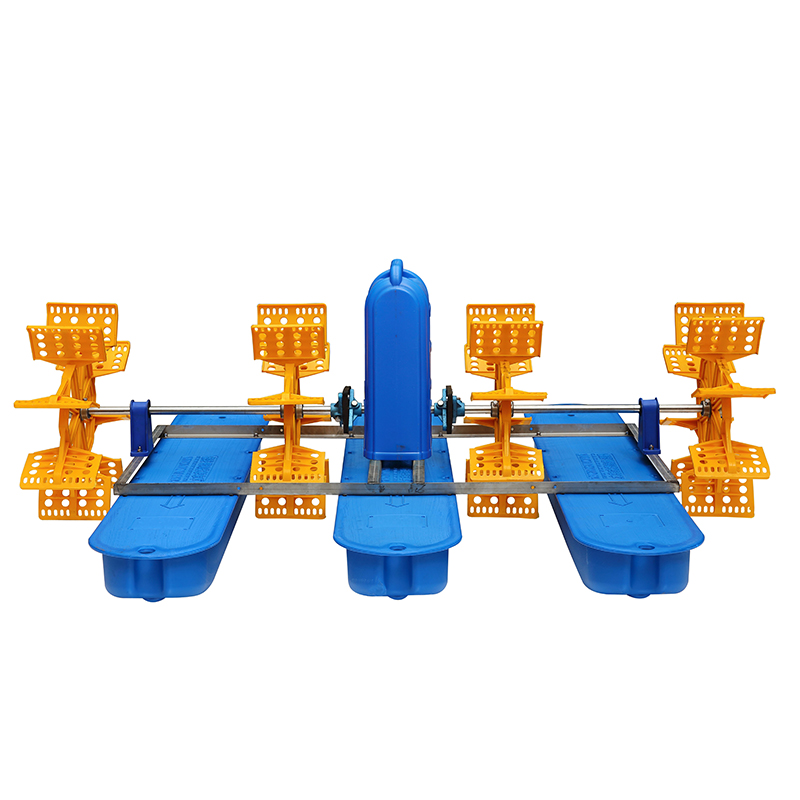

2HP 4 impeller paddle wheel aerator

|

Model

|

HP

|

Voltage

(V)

|

Frequency

|

Impellers

|

AMP(A)

|

Power Efficiency (kg/kw.h)

|

Aerobic capacity (kg/h)

|

Impeller Speed (Rpm)

|

|

SC-0.75

|

1

|

220V-440V

|

50/60HZ

|

2

|

1.2

|

≥1.25

|

≥1.1

|

106

|

|

SC-1.5

|

2

|

220V-440V

|

50/60HZ

|

4

|

2.5

|

≥1.25

|

≥1.9

|

106

|

|

SC-1.5

|

2

|

380V -440V

|

50/60HZ

|

6

|

2.8

|

≥1.5

|

≥3.8

|

106

|

|

SC-2.2

|

3

|

380V-440V

|

50/60HZ

|

6

|

2.8

|

≥1.5

|

≥3.8

|

106

|

|

SC-2.2

|

3

|

380V-440V

|

50/60HZ

|

8

|

3

|

≥1.5

|

≥4.3

|

106

|

|

SC-3.0

|

4

|

380V-440V

|

50/60HZ

|

10

|

3

|

≥1.5

|

≥5

|

106

|

|

SC-3.0

|

4

|

380V-440V

|

50/60HZ

|

12

|

3.2

|

≥1.5

|

≥5.5

|

106

|